EAGL Wireless monitoring system

Key points

4 sensors in one wireless unit

- 3 vibration axes

- bearing Temperature

Monitoring of alarms

- short periodicity for monitoring vibration velocity, acceleration and temperature

- storage of raw data at a larger periodicity and on any alarm occurrence

- optimization of battery lifetime

Communication capabilities

- automatic and extended communication capabilities

- smart wireless protocol: no setup needed

- up to 100 meters between the gateway and the first node

- up to 7 expanders between the sensor and the gateway

Made for diagnostic

- analysis of phenomenon up to 20kHz

- dynamic range of +/- 50g

- one or several time waveforms and FFT per point, including envelope FFT

- up 16,384 samples per time waveform (0.3s with Fmax = 20kHz, 0.6s with Fmax = 10kHz…)

Operating conditions

- measurements are done in specific conditions (speed, power…)

- easy trending and diagnostics

- optimization of battery lifetime

Features

Ease of deployment

Harsh environments

EAGLE solution has been designed to meet the industry requirements. Both the EAGLE sensor and the Expander are certified for use in explosive area Zone 0 (Class I, Div I). The stainless steel body with very low thermal expansion makes it safe to use even in the harshest settings. IP67, EAGLE is also resistant against corrosive environments. Wireless and automatic, EAGLE eliminates the need for cables and manual inspections where conditions are not conducive for such operations.

Managing machines with variable conditions

-

measurements can be easily translated into trends and compared over time for each operating condition

-

no false alarms: thresholds are adjusted for each operating condition, providing accurate fault detection capabilities on complex machinery

Temporary monitoring

Depending on the condition monitoring strategy, many machines may be monitored using portable data collection, where vibration measurements are performed manually at scheduled intervals (e.g. every month). EAGLE is easy to install, and also easy to move: once a fault is identified on a critical machine, it is now possible to move EAGLE sensors to monitor the machine condition with much shorter intervals (e.g. every hour), to avoid any unexpected failure, improve the overall availability of the process, and schedule maintenance operation only if that’s really necessary.

Monitoring of critical machinery

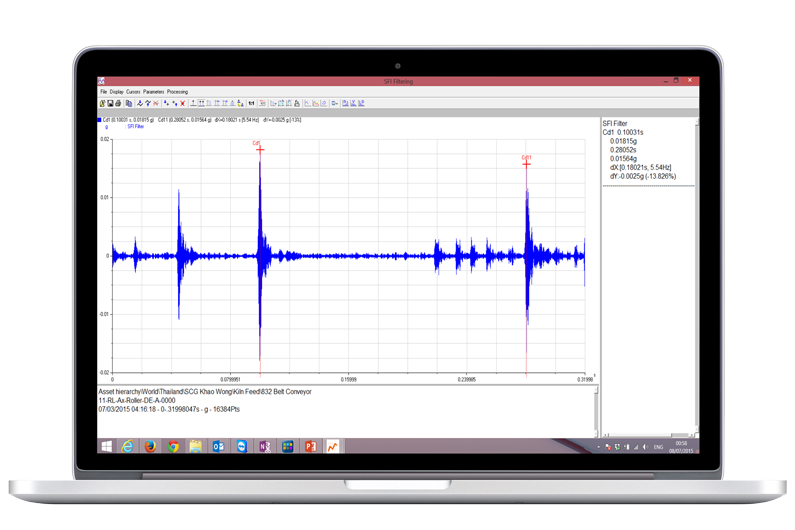

EAGLE is the wireless system offering the best performance on the vibration analysis market. Its measurements quality makes it suitable for monitoring any rotating machine, from 100 rpm upwards. EAGLE is not just a transducer. This smart wireless unit embeds signal processing: Advanced indicators, as well as envelope FFT are calculated locally, thus enabling measurements to be recorded if a vibration or bearing temperature alarm occurs. The data storage frequency is adjusted automatically according to the machine condition. Data is available for detailed analysis using ONEPROD NEST predictive maintenance platform, providing unique tools such as the ONEPROD Shock Finder™ filter. Maintenance operations can be scheduled before any failure occurs.

Ease of maintenance

EAGLE performance is optimized for long term service with a low cost of maintenance: The EAGLE battery offers up to 5 years availability under rated operating conditions of one full diagnostic measurement set per day, and this with no external source of power supply or maintenance operations. For critical machinery, using an optimum monitoring strategy with frequent alarm monitoring and storage of high quality data (Overals, Time waveform, FFT, envelope), EAGLE still offers a 2-year lifetime. Moreover, the inexpensive standard battery is interchangeable on-site by the end user, making its replacement easy to achieve.

Product Video

Download Brochure

Technical Datasheet

Find The Right Device

Then please get in touch and we'll be glad to help.