1. Aligning Machines with 3 or unconventional feet

Some machines are not manufactured with a typical 4 footed configuration. Precision shaft alignments can still be easily accomplished on these “non-typical” machine configurations, if you remember a couple of simple rules.

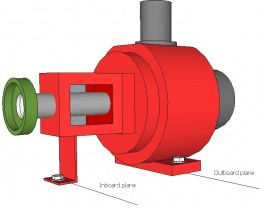

When aligning a machine with three feet, like this example, remember that you are positioning machinery in two planes:

The inboard, or drive end, and

the outboard, or opposite drive end.

The outboard end will be treated as usual, and the inboard end will simply be shimmed and/or adjusted at the one foot.

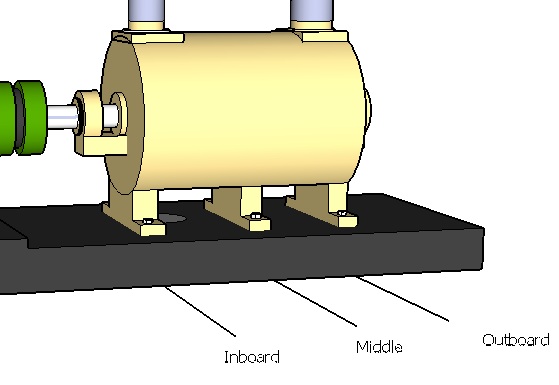

When aligning a machine with six feet, another foot plane is introduced. The inboard and outboard feet will be treated the same as a four-footed machine configuration, but the middle feet (plane) can be corrected using this method:

After the inboard and outboard feet shim corrections have been made, simply use a feeler gauge to determine the amount of shim required to “fill in” under the middle feet.You can snug the inboard and outboard feet before making the shim correction to the middle feet.

On large machines, you may want to add an additional 2-3 mils of shim under the middle feet, to compensate for any “sag” due to weight.

Some laser shaft alignment tools can calculate the middle feet shim requirement based on the distance from the center of the coupling to the middle feet. However, this calculation is based on the assumption that the base is completely flat, which often it is not.

On a “standard” machine configuration, the four feet establish a “plane”. But when two additional feet are introduced, you should not assume they are in the same exact plane.

2. Vibration excitation due to weak support

Find The Right Device

Then please get in touch and we'll be glad to help.